The rise of electric vehicles has been nothing short of transformative, reshaping how we think about transportation, energy consumption, and sustainability. Central to this revolution is a small but mighty component: the lithium battery. Over the past decade, advances in chemistry, materials science, and manufacturing processes have turned the lithium battery from a niche component into the heart of modern electric cars. As manufacturers push the boundaries of range, performance, and cost, the evolution of the lithium battery remains the key driver behind the expanding electric car market.

From Early Innovations to Modern Powerhouses

The story of the lithium battery began in the 1970s with the first commercial lithium‑ion cell, but it wasn’t until the early 2000s that battery technology matured enough to power full‑size electric cars. Improvements in cathode materials—such as nickel‑cobalt‑aluminum (NCA) and nickel‑manganese‑cobalt (NMC) chemistries—have significantly boosted energy density while reducing weight. On the anode side, graphite has largely been supplanted by silicon‑graphite blends, which can store more charge without compromising safety.

- Higher energy density allows for longer driving ranges per charge.

- Advanced thermal management systems keep lithium batteries operating within optimal temperature windows.

- Robust safety protocols reduce the risk of thermal runaway incidents.

The Lithium Battery’s Influence on Electric Car Performance

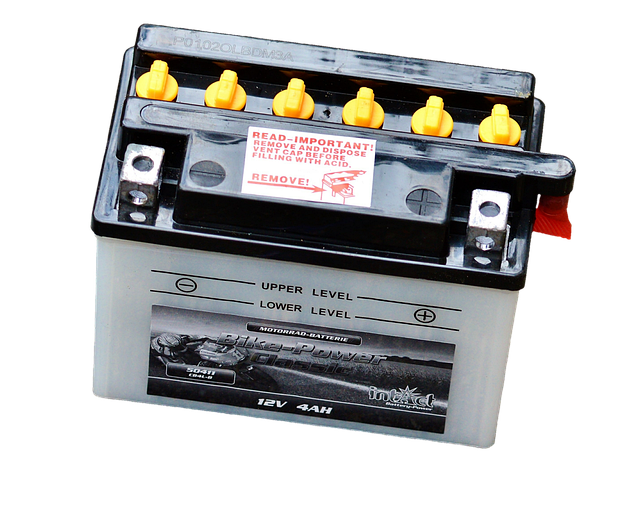

A lithium battery’s performance characteristics directly translate into everyday driving experience. Fast charging capabilities mean drivers can replenish their vehicles in minutes rather than hours, while high power output ensures strong acceleration and smooth power delivery. Moreover, the lightweight nature of modern lithium cells reduces the overall mass of the vehicle, improving efficiency and handling.

“The integration of high‑energy lithium batteries is what makes electric cars competitive with internal combustion engines on range and speed.” – Automotive Engineer, Global Mobility Research Center

Battery Management Systems (BMS) and Vehicle Integration

Every modern electric car relies on a sophisticated Battery Management System (BMS) to monitor voltage, temperature, and state of charge across thousands of individual cells. The BMS ensures that each cell operates within safe limits, extends the battery’s lifespan, and optimizes overall performance. By balancing charge across cells, the BMS mitigates degradation that can arise from uneven wear.

- Real‑time monitoring of cell health.

- Adaptive charging strategies to reduce heat buildup.

- Predictive maintenance alerts for service teams.

Electric Car Service: Adapting to Lithium Battery Technology

Service technicians have had to adapt to a new set of challenges when working with electric vehicles. Diagnostics now involve software tools that interface with the BMS, allowing technicians to retrieve detailed data on cell performance and health. Furthermore, the high voltage systems used in lithium batteries require specialized safety protocols, including the use of insulated tools and comprehensive grounding procedures.

- Training programs now include modules on battery safety and diagnostics.

- Diagnostic tools are often cloud‑connected for remote support.

- Recycling and disposal of spent lithium batteries follow strict environmental regulations.

Replacing and Upgrading Battery Packs

As electric cars age, the degradation of lithium batteries can lead to reduced range. Vehicle owners and service centers now have two primary options: replace the entire battery pack or upgrade to a higher‑capacity pack. The cost of replacement has dropped significantly, thanks to economies of scale and improved manufacturing efficiencies. Some manufacturers offer battery leasing programs, allowing owners to swap out batteries as technology advances.

- Standard replacement: swap the existing pack for a new, same‑capacity pack.

- Capacity upgrade: install a larger pack to increase range.

- Battery leasing: replace the pack periodically under a subscription model.

Car Parts and Components: Beyond the Battery

The lithium battery’s integration into the vehicle has spurred development across a wide array of car parts. Power electronics, such as inverters and DC‑DC converters, must be finely tuned to interface with the battery’s voltage range. Cooling systems now include dedicated liquid loops or phase‑change materials that keep the battery at an optimal temperature. Even the vehicle’s chassis design is influenced, with designers creating lower centers of gravity to accommodate the battery’s placement beneath the floor.

“Every component, from the tire to the infotainment system, is being re‑engineered to complement the high‑performance lithium battery.” – Vehicle Design Lead, Future Mobility Solutions

Emerging Materials for Enhanced Battery Life

Research into new electrode materials is ongoing. Researchers are exploring solid‑state electrolytes that could replace the flammable liquid electrolyte in traditional lithium batteries, potentially offering higher energy density and improved safety. Additionally, research into sodium‑ion chemistry aims to reduce dependence on scarce cobalt, a key component in many lithium‑ion cathodes.

- Solid‑state electrolytes for higher energy density.

- Sodium‑ion batteries for cost‑effective production.

- Graphene‑enhanced electrodes for faster charge and discharge cycles.

Future Trends: What Lies Ahead for Lithium Battery‑Powered Cars

Looking forward, the trajectory of lithium battery technology points toward even greater efficiency, lower costs, and faster charging times. Governments and manufacturers are investing heavily in battery recycling infrastructure, which will reduce the environmental footprint of electric vehicles and help secure supply chains for critical materials. Furthermore, the advent of vehicle‑to‑grid (V2G) technology will allow lithium batteries to serve as distributed energy storage, feeding excess renewable energy back into the grid.

“The next decade will see lithium batteries not just powering cars, but becoming integral components of the broader energy ecosystem.” – Energy Policy Analyst, National Renewable Energy Agency

Charging Infrastructure Evolution

Charging stations are moving from 50‑kW to 350‑kW systems, cutting charging times from an hour to just 20–30 minutes for high‑capacity packs. Smart charging networks use real‑time data to balance grid load and optimize battery usage. Moreover, wireless charging technologies are being tested in real‑world environments, enabling vehicles to charge while parked or even while driving on special induction lanes.

- High‑power DC fast charging stations.

- Smart grid‑integrated charging networks.

- Wireless induction charging for convenience.

Conclusion: The Lithium Battery as the Cornerstone of Sustainable Mobility

In the journey from experimental prototypes to mass‑produced electric cars, the lithium battery has emerged as the indispensable power source that makes electric mobility feasible at scale. Its continual improvement in energy density, safety, and cost has directly enabled longer ranges, quicker acceleration, and more affordable vehicles. As service ecosystems adapt and new materials push the boundaries further, the lithium battery will remain the linchpin of the electric vehicle industry, guiding us toward a cleaner, more efficient transportation future.