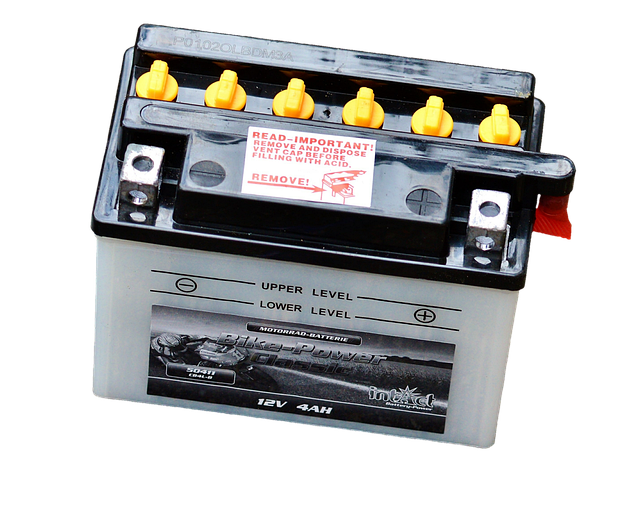

The rise of electric vehicles has brought a new focus to the health and longevity of their power sources. Engineers and technicians are now regularly performing battery self‑tests to monitor cell performance, identify degradation early, and extend the usable life of each pack. A battery self‑test uses onboard diagnostics, voltage and temperature readings, and advanced algorithms to predict remaining range and detect potential failures before they become critical. By integrating this process into routine service visits, manufacturers are reducing unexpected downtime and giving owners more confidence in their vehicle’s reliability.

How a Battery Self‑Test Works

During a battery self‑test, the vehicle’s management system runs a series of voltage checks, internal resistance measurements, and thermal scans. The data are then compared against factory benchmarks and historic trends. If a cell’s voltage deviates beyond a predefined threshold, the system flags it as potentially defective. Similarly, a rise in internal resistance indicates chemical aging, which translates into reduced capacity and efficiency. By correlating these metrics, the system calculates a health score, often expressed as a percentage of the original capacity. A battery self‑test can also identify imbalances between individual cells, which, if left unchecked, can accelerate degradation.

- Voltage profiling of every cell in the pack.

- Measurement of internal resistance to gauge aging.

- Temperature mapping to detect hot spots.

- Comparison to baseline data for trend analysis.

Benefits of Regular Battery Self‑Tests

Regular battery self‑tests help service centers and owners anticipate problems before they affect daily driving. The key advantages include:

“A proactive battery self‑test strategy reduces warranty claims and improves customer satisfaction,” says a senior technician at a major dealership.

- Early detection of cell failures.

- Optimized charging schedules to maintain cell balance.

- Reduced risk of thermal runaway.

- Accurate range estimation for better trip planning.

New Parts on the Market for Battery Maintenance

The industry has seen a surge in aftermarket components designed to support battery health. Among the most noteworthy additions are modular cell balancers, high‑capacity replacement cells, and advanced thermal management kits. These parts not only improve performance but also extend the life of existing packs. Vehicle owners can now choose from a range of options that fit their driving habits and budget.

- Modular Cell Balancers: Automatically equalizes charge across cells, preventing uneven wear.

- High‑Capacity Replacement Cells: Provide more energy density, increasing range by up to 10%.

- Thermal Management Kits: Use liquid cooling or phase‑change materials to keep temperatures stable.

- Smart BMS Upgrades: Enhance diagnostics and provide more granular data during battery self‑tests.

Impact on Car Engines and Powertrains

While battery self‑tests focus on the power source, they indirectly influence the performance of electric car engines and motor systems. A healthy battery delivers consistent voltage, which improves torque delivery and reduces motor strain. Conversely, a degraded battery can cause power dips, leading to sudden braking or reduced acceleration. By monitoring battery health, service technicians can make informed decisions about whether to adjust motor control algorithms or recommend component replacements.

Recent News in Battery Technology

Several breakthroughs have recently emerged in battery research. Researchers at a leading university announced a new electrolyte formulation that reduces internal resistance by 30%, while a private company unveiled a solid‑state battery prototype that promises to double safety margins. These advances are expected to influence the next generation of electric cars, making battery self‑tests even more critical as packs become more complex and higher performing.

Service Tips for Car Owners

Owners looking to maintain their vehicle’s battery health should follow a few simple guidelines. First, avoid deep discharging; keeping the state of charge between 20% and 80% can minimize stress on cells. Second, use the manufacturer’s recommended charging stations whenever possible, as they are calibrated for optimal voltage and temperature ranges. Third, schedule a battery self‑test every 12 months or after a major trip to catch any emerging issues.

“Even a brief self‑test can save you from a costly replacement later,” advises a seasoned mechanic who specializes in electric vehicles.

Conclusion

Battery self‑test procedures have become a cornerstone of modern electric car maintenance. By offering early detection of cell wear, facilitating proactive part replacement, and ensuring consistent performance across the powertrain, these tests help keep electric vehicles on the road longer and safer. As new parts and technologies enter the market, the importance of integrating battery self‑tests into regular service routines will only grow. Whether you’re a dealership technician or an everyday driver, staying informed about battery health and maintenance strategies is essential for enjoying the full benefits of electric mobility.