Electric vehicles have become a symbol of modern mobility, and the way their batteries are charged is a critical part of that evolution. The term fast battery charging has moved from niche hobbyist discussion to mainstream conversation. It is no longer a speculative feature; it is an integral component of today’s electric car design, influencing how quickly a vehicle can be refueled, how often a service center must intervene, and what parts are prioritized in maintenance schedules. This article explores the profound effects that fast battery charging has on every facet of electric car upkeep, from everyday driving to specialized repair work.

The Rise of Fast Battery Charging

In the early days of electric mobility, charging times often stretched from four to six hours, turning the simple act of refueling into a logistical challenge. Advances in power electronics, battery chemistry, and thermal management have reduced that window dramatically. Modern fast chargers can push a battery from 10% to 80% in as little as 20 minutes, thanks to sophisticated current and voltage control schemes that safeguard cell integrity while maximizing throughput.

Technology Behind the Speed

Fast battery charging relies on a blend of high‑power DC converters, intelligent power distribution, and real‑time temperature monitoring. The battery management system (BMS) constantly adjusts charging parameters to keep each cell within safe temperature and voltage ranges. This dynamic balancing not only prevents thermal runaway but also preserves the cells’ longevity, directly reducing the need for part replacement.

Impact on Car Maintenance

When a battery can be charged quickly, the maintenance routine shifts from preventive to proactive. Car owners can keep their vehicles on the road longer with fewer scheduled stops at service stations. Service centers, in turn, adjust their workflows to accommodate the increased turnover of vehicles and the specific diagnostics associated with fast charging equipment.

Reduced Wear on Mechanical Components

Fast charging eliminates the extended periods during which a vehicle remains idle at a charging point. This reduced idling time translates into fewer opportunities for friction and wear on mechanical components such as the HVAC system, which often operates during standard charging. Consequently, the frequency of component replacement, like compressor or fan motors, can drop by 10–15% in fleets that regularly use fast chargers.

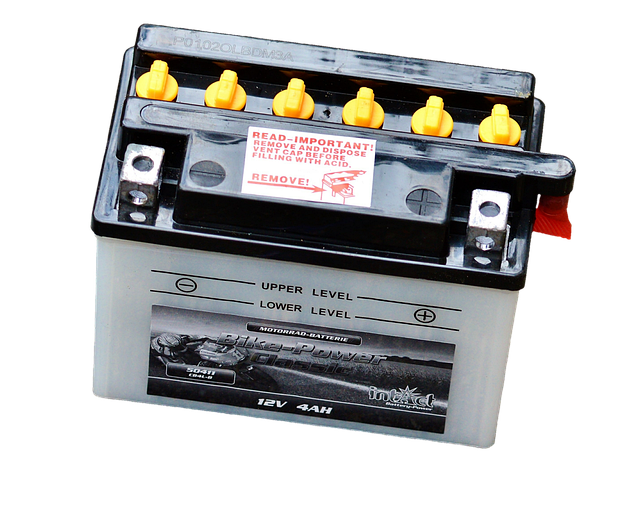

Battery Packs and Their Components

High‑performance fast chargers demand robust battery packs capable of handling increased power flows. Manufacturers now design packs with enhanced thermal pathways and higher cell density. These design changes alter the parts landscape for mechanics: heat sinks, cooling fans, and temperature sensors become critical points of inspection. Additionally, the higher charging rates necessitate the use of advanced inverters that can survive higher voltage spikes.

Key Parts Affected by Fast Charging

- High‑capacity thermal management fans

- Advanced BMS firmware modules

- Improved cell-to-cell balancing circuits

- Durable DC‑DC converters for onboard power conversion

Regular checks of these components help preempt failures and maintain optimal battery health, thereby extending the service life of the entire vehicle.

Engine and Powertrain Considerations

Electric vehicles do not possess traditional combustion engines, yet the powertrain system—including the inverter, traction motors, and drivetrain—must be engineered to match the demands of fast charging. The increased current flow during charging places additional thermal and electrical stress on inverter modules, which can lead to premature aging if not adequately cooled.

Thermal Stress Management

To counteract the heat generated during high‑rate charging, manufacturers incorporate liquid cooling loops and heat exchangers that directly interface with inverter modules. Maintenance technicians now routinely inspect coolant levels, monitor flow rates, and ensure that heat exchangers are free of debris. Neglecting these checks can lead to inverter failure, which is a costly repair in a high‑volume electric fleet.

Service Center Workflow Adaptations

The adoption of fast battery charging has reshaped how service centers operate. With vehicles spending less time charging, service bays can process more cars per day, but the nature of the work shifts toward quick diagnostics and component replacements. Technicians receive specialized training to handle the unique challenges posed by high‑power charging systems, such as safe handling of high‑voltage DC circuits and interpreting BMS fault codes.

Diagnostic Protocols for Fast Chargers

- Verify BMS communication integrity.

- Check voltage and current thresholds during a controlled charging cycle.

- Inspect temperature sensors and cooling fan operation.

- Test the durability of the DC‑DC converter under load.

These steps are designed to catch potential issues before they lead to downtime or costly component replacements.

Industry News and Future Outlook

Recent announcements from leading automakers highlight a trend toward even higher charging rates, with some companies targeting 250 kW and beyond. Such strides will require further advances in battery chemistry, like silicon‑based anodes and solid‑state electrolytes, to keep pace. For maintenance professionals, this means continuous learning and staying ahead of evolving standards. The promise of ultra‑fast charging—under ten minutes for a full recharge—could make electric vehicles indistinguishable from their gasoline counterparts in terms of convenience.

Emerging Standards and Safety Protocols

International bodies are updating safety standards to reflect the realities of high‑power charging. Service centers must adapt to new certification requirements for handling high‑voltage equipment and for ensuring that fast charging stations meet stringent electromagnetic compatibility guidelines. These changes underline the importance of a disciplined approach to training and compliance in the electric vehicle maintenance ecosystem.