Electric vehicles have emerged as a cornerstone of the sustainable mobility revolution. From city commutes to long‑haul trucking, the shift away from internal combustion engines is accelerating at a pace that outstrips many expectations. Central to this transition is the way battery modules are designed, manufactured, and integrated into the vehicle architecture. The phrase “battery packaging” has entered the mainstream lexicon of automotive engineers and technicians alike, as the physical arrangement and thermal management of cells can make the difference between a car that feels sluggish and one that bursts with responsiveness.

Design Trends That Shape Battery Packaging

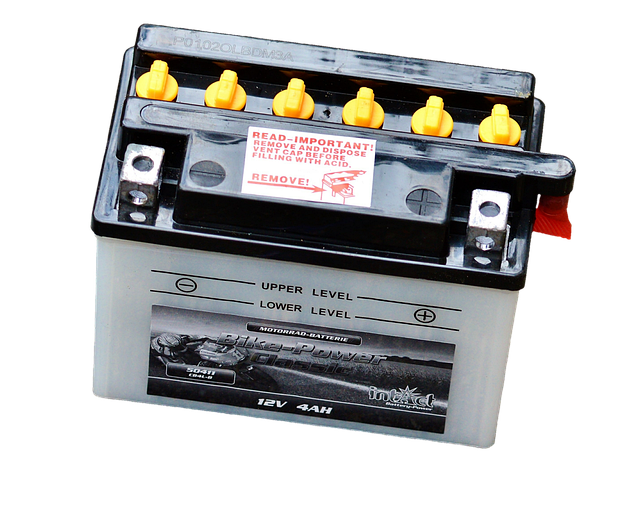

Recent years have seen a move away from the traditional, box‑shaped packs that dominated early EV models. Manufacturers are experimenting with cylindrical, pouch, and even prismatic cells arranged in a honeycomb or modular lattice. Each geometry brings unique advantages for thermal stability, mechanical resilience, and ease of maintenance.

One emerging trend is the “cylindrical‑core” concept, where a high‑capacity cell serves as the spine of the pack. This arrangement simplifies heat exchange and allows technicians to replace a single core without disturbing the surrounding modules. Another is the adoption of a “dual‑zone” design, separating high‑energy cells from high‑power cells. This segmentation reduces the risk of thermal runaway and gives service centers a clearer diagnostic map during fault isolation.

Impact on Vehicle Performance

The way cells are arranged influences not only energy density but also power delivery. A tightly packed, thermally optimized module can deliver bursts of torque that feel immediate at the wheel. Conversely, a design that prioritizes weight reduction may compromise heat removal, leading to periodic power curtailment during prolonged acceleration.

Service technicians are finding that battery packaging directly affects how a car behaves in real‑world driving. Vehicles with a modular “top‑down” layout often report smoother acceleration curves because heat dissipates more evenly across the pack. In contrast, “bottom‑up” configurations can create hotspots that trigger the thermal management system to throttle performance to protect the cells.

Service Implications of Modern Packaging

When a battery pack is engineered for easy disassembly, technicians can isolate a faulty cell without dismantling the entire module. This modularity translates into faster diagnostics, lower labor costs, and shorter downtime for owners. The rise of “plug‑and‑play” battery modules means service shops can swap a defective unit for a fresh one in under an hour, preserving resale value and customer confidence.

However, newer packaging approaches also introduce complexity in thermal monitoring. High‑density packs generate heat at a faster rate, requiring more sophisticated temperature‑sensor arrays that must be calibrated regularly. Failure to maintain accurate sensor data can lead to premature battery degradation or unexpected shutdowns, which erode trust in the vehicle’s reliability.

Safety and Thermal Runaway Mitigation

Battery packaging plays a pivotal role in preventing thermal runaway—a condition where a cell overheats and spreads to neighboring cells, potentially leading to fire. Modern packs often incorporate passive cooling layers, such as aluminum honeycomb or phase‑change materials, to absorb heat spikes. Additionally, designers are integrating electronic safeguards that detect abnormal voltage gradients across the pack and initiate controlled shutdowns before a fault escalates.

“A well‑engineered pack is not only a performance booster but a safety net that protects drivers from catastrophic failures.”

Recent Industry Developments

Automakers are announcing collaborations that focus on standardizing battery packaging to streamline production and facilitate second‑hand markets. One notable initiative is the global battery module alliance that aims to develop a universal cell format, enabling interchangeable parts across different brands. The push toward modularity is expected to lower costs for both manufacturers and consumers while improving part availability for service centers.

Meanwhile, regulatory bodies are tightening safety standards around battery packaging. New guidelines now require that every pack undergoes a mandatory high‑temperature cycle test and that thermal‑conductive materials meet stringent emission limits. Compliance with these regulations will influence how quickly new battery designs can reach the market.

Looking Ahead: What Comes Next?

Battery packaging will likely continue to evolve toward lighter, more efficient designs that enable higher mileage per charge. Engineers are exploring the integration of self‑healing polymers that can seal micro‑cracks before they propagate, reducing long‑term degradation. Other research focuses on wireless thermal sensors that transmit data to a central hub, eliminating the need for hardwired connections that can fail over time.

For service networks, this means an increased need for diagnostic software that can interpret data from heterogeneous sensor ecosystems. Training programs for technicians will shift from basic cell replacement to advanced diagnostics, with a stronger emphasis on data analytics and predictive maintenance.

Concluding Thoughts

In the fast‑moving world of electric mobility, battery packaging is more than a technical detail—it is a linchpin that ties together performance, safety, cost, and serviceability. As vehicle manufacturers push the envelope with ever more compact and efficient packs, service centers must stay ahead of the curve with updated tools, training, and data‑centric diagnostics. The partnership between design, production, and after‑sales support will determine whether the next generation of electric cars delivers on the promise of range, reliability, and safety for everyday drivers.

Impact on Car Service Networks and Customer Experience

The way a battery pack is packaged influences how service technicians approach routine maintenance. In the early days of EVs, most repairs involved swapping entire packs—a costly and time‑consuming process. Modern packaging that allows quick access to individual cells or modules means technicians can perform “in‑shop” replacements, reducing downtime and keeping customers on the road.

Customers are increasingly sensitive to the total cost of ownership. A battery pack that can be serviced efficiently reduces long‑term repair costs and extends the vehicle’s useful life. Additionally, transparent diagnostic workflows that communicate battery health in simple metrics help build trust, turning routine visits into opportunities for proactive education about range‑optimizing habits.

Technological Synergies with Other Car Parts

Battery packaging does not exist in isolation; it interacts with thermal management systems, regenerative braking electronics, and even chassis design. By aligning the pack’s heat profile with the vehicle’s cooling architecture, manufacturers can achieve lower overall energy consumption. In some models, the battery pack doubles as a structural component, adding rigidity to the floorpan and reducing the need for additional reinforcement.

Electrification of powertrains also drives demand for high‑efficiency power electronics that interface seamlessly with the pack’s voltage and current characteristics. As a result, the evolution of battery packaging often parallels advancements in inverter technology, DC‑DC converters, and electric motor design, creating a virtuous cycle that boosts performance while keeping costs manageable.