The global shift toward electrification of the transportation sector has brought battery environmental protection to the forefront of automotive conversations. As electric cars (EVs) become more common on roads worldwide, the entire supply chain—from raw material extraction to end-of-life disposal—faces scrutiny for its environmental footprint. This article examines how battery environmental protection can be woven into electric car service practices, ensuring that the journey to a greener future remains sustainable from the first mile to the last. The focus is on the intersection of electric car technology, car service operations, and the stewardship of critical battery components, while keeping the narrative grounded in factual, actionable information.

The Rise of Electric Vehicles and Battery Sustainability

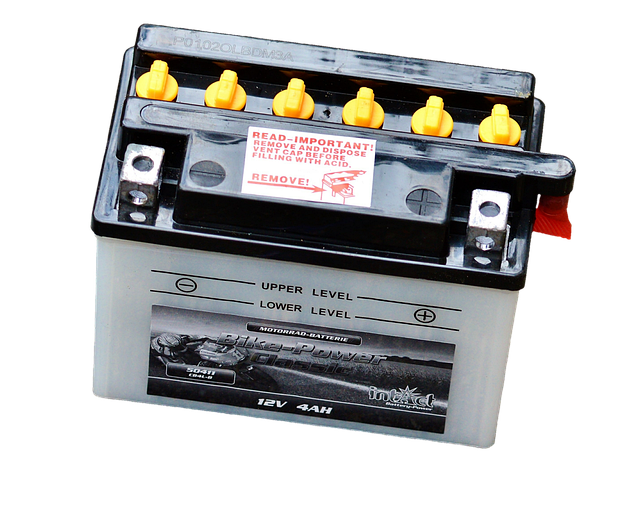

Electric vehicles promise reduced greenhouse gas emissions, lower dependence on fossil fuels, and quieter streets. However, the environmental benefits of EVs hinge on responsible battery management. Lithium-ion batteries, the most common power source for modern EVs, contain valuable metals such as lithium, cobalt, nickel, and graphite. The extraction and processing of these materials, if not managed properly, can lead to significant ecological damage, including habitat disruption, water contamination, and high energy consumption.

Battery environmental protection is therefore not merely an afterthought; it is a core component of the EV value chain. Effective protection strategies involve reducing the environmental impact of mining, improving manufacturing efficiencies, promoting recycling, and extending battery lifespan through proper maintenance and service.

Core Components of Battery Environmental Protection

Achieving comprehensive battery environmental protection requires a multi‑layered approach. Key elements include:

- Material Sourcing – Selecting suppliers that adhere to ethical mining practices and environmental certifications.

- Design for Durability – Engineering batteries with longer operational lifespans and higher energy density.

- Manufacturing Efficiency – Reducing waste, energy use, and emissions during battery production.

- Service and Maintenance – Providing technicians with specialized training to optimize battery performance and safety.

- Recycling and Upcycling – Establishing closed‑loop systems to recover and reuse battery components.

Each of these elements interlocks, creating a framework that guides the entire life cycle of an electric car’s battery from cradle to grave.

Green Practices in Electric Car Service

Car service centers serve as pivotal nodes in the battery environmental protection chain. By adopting green practices, service providers can reduce emissions, conserve resources, and extend battery life. Core green service practices include:

- Temperature‑Controlled Charging – Maintaining optimal thermal conditions during charging prevents degradation and reduces energy waste.

- Battery Health Diagnostics – Advanced diagnostics identify early signs of wear, enabling preventive maintenance that saves battery capacity.

- Energy‑Efficient Workflows – Using renewable energy sources for shop lighting, HVAC, and equipment reduces the carbon footprint of service activities.

- Waste Minimization – Proper segregation and disposal of hazardous materials prevent environmental contamination.

- Customer Education – Informing owners about optimal charging habits and maintenance schedules fosters responsible battery use.

By embedding these practices into daily operations, service centers not only protect the battery’s integrity but also reinforce the broader environmental mission of electric mobility.

Temperature‑Controlled Charging: A Closer Look

Lithium‑ion cells are sensitive to temperature extremes. Charging at high temperatures accelerates electrolyte breakdown, while low temperatures can limit ion mobility. Service centers equipped with thermal management systems—such as active cooling or heating loops—maintain a stable environment. This reduces internal resistance, preserves energy density, and mitigates the risk of thermal runaway. Implementing smart charging protocols that adjust power levels based on real‑time temperature data further optimizes battery longevity.

Battery Health Diagnostics

Modern diagnostics employ a suite of sensors and algorithms to evaluate state of health (SoH), state of charge (SoC), and internal resistance. By regularly monitoring these metrics, technicians can pinpoint issues such as cell imbalance, electrolyte loss, or degradation hotspots. Early detection allows for targeted interventions—like cell balancing or partial replacement—before minor problems evolve into major failures. Consistent diagnostic checks also feed valuable data into predictive maintenance models, enhancing service reliability.

Battery Recycling and Upcycling

When a battery reaches the end of its usable life, responsible recycling becomes paramount. Battery environmental protection hinges on the ability to recover critical metals and safely dispose of hazardous components. Key steps in a robust recycling process include:

- Pre‑processing – Removing connectors, casings, and auxiliary electronics to isolate the battery pack.

- Thermal or Hydrometallurgical Treatment – Using heat or chemical leaching to extract metals such as lithium, cobalt, and nickel.

- Purification and Re‑refining – Cleaning recovered metals to industrial purity for reuse in new batteries or other applications.

- Material Re‑utilization – Incorporating recovered components into secondary battery applications or other high‑tech industries.

- Hazardous Waste Management – Safely disposing of residual acids, solvents, and heavy metals.

Advanced upcycling initiatives also repurpose spent batteries into stationary storage solutions, such as home energy storage or grid‑scale backup, extending the useful life of the materials beyond automotive use. These practices close the loop and significantly reduce the need for new mining.

Hydrometallurgical Recovery: An Eco‑Friendly Approach

Hydrometallurgy uses aqueous solutions to dissolve and separate metals from spent battery cells. Compared to pyrometallurgical methods, it typically consumes less energy and produces fewer emissions. By carefully controlling pH, temperature, and reagent composition, the process achieves high metal recovery rates while minimizing the release of toxic substances. The resulting metal solutions can then be precipitated, purified, and converted back into electrode-grade materials.

Role of Car Service Centers in the Recycling Pipeline

Service centers can act as collection hubs for used batteries, providing a first step in the recycling chain. Key responsibilities include:

- Battery Retrieval – Safely removing batteries from vehicles for storage or direct handover to recyclers.

- Condition Assessment – Classifying batteries as reusable, refurbishable, or recyclable based on health metrics.

- Secure Storage – Maintaining temperature and safety controls to prevent fire risk during storage.

- Documentation – Tracking battery origin, composition, and service history to facilitate traceability.

- Customer Incentives – Offering service discounts or rebates for customers who return used batteries.

By integrating battery collection into their service workflow, centers reinforce the circular economy and enhance the overall sustainability of the EV ecosystem.

Emerging Technologies and Standards

The battery environmental protection landscape is evolving rapidly, driven by research, policy, and market forces. Some of the most promising developments include:

- Solid‑State Batteries – Replacing liquid electrolytes with solid materials to improve safety, reduce flammability, and increase energy density.

- Battery Management Systems (BMS) 4.0 – Integrating AI and edge computing to predict degradation patterns and optimize charging strategies in real time.

- International Standards (ISO, IEC) – Establishing guidelines for battery design, safety, and recycling to ensure consistency across global supply chains.

- Regulatory Incentives – Tax credits, subsidies, and extended warranties for vehicles that meet stringent battery environmental protection criteria.

- Blockchain Tracking – Providing transparent supply chain records for raw material sourcing and end‑of‑life handling.

Adopting these technologies not only enhances battery performance but also fortifies the environmental safeguards embedded within the EV service ecosystem.

Solid‑State Battery Breakthroughs

Solid‑state batteries eliminate the liquid electrolyte that can be prone to leakage and flammability. Early prototypes demonstrate higher energy densities—up to 50% greater than conventional lithium‑ion cells—and improved safety profiles. For service centers, this translates into lower fire‑risk protocols and potential cost savings on safety equipment.

AI‑Driven Battery Management

By deploying machine learning algorithms within BMS units, technicians can gain predictive insights into battery health. The system can autonomously adjust charging rates, cool the pack, or schedule maintenance before performance drops noticeably. This proactive approach extends battery life and reduces the need for costly replacements.

Future Outlook

The trajectory toward a fully circular battery economy is gaining momentum. In the next decade, we can anticipate:

- Widespread adoption of standardized recycling protocols that streamline material recovery.

- Integration of renewable energy into service centers, powering diagnostics and charging equipment.

- Enhanced consumer awareness leading to higher rates of battery return and refurbishment.

- Regulatory frameworks that mandate battery environmental protection as part of vehicle certification.

- Greater collaboration among manufacturers, service providers, and recyclers to share best practices.

As these trends converge, battery environmental protection will move from a compliance requirement to a competitive advantage, driving industry leaders toward greener, more sustainable business models.

Conclusion

Battery environmental protection sits at the heart of responsible electric vehicle stewardship. From sourcing to servicing, each step influences the ecological footprint of the entire vehicle. By embedding green practices in car service operations, embracing cutting‑edge recycling methods, and staying attuned to emerging technologies, the automotive industry can ensure that the promise of electric mobility is matched by genuine environmental stewardship.