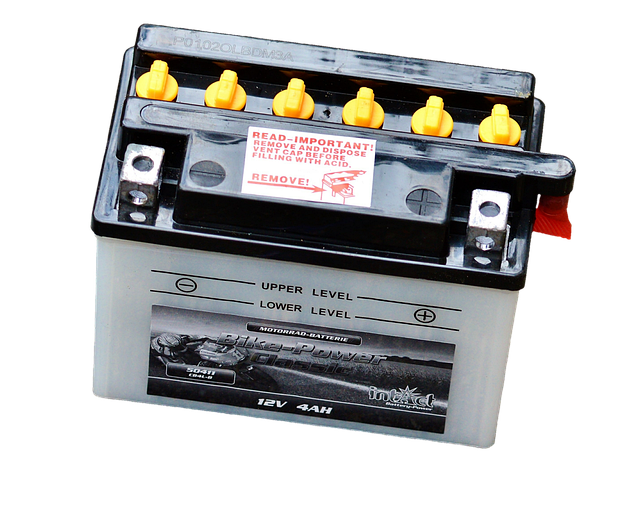

Electric vehicles are redefining mobility, and at the heart of every battery‑powered car lies a complex network of components that keep it running. Among these, the battery clamp is a small but critical part of the charging and discharging system. Though it may be overlooked by the casual observer, a properly installed and maintained battery clamp ensures reliable connections, protects against corrosion, and reduces the risk of electrical failures. As manufacturers push the limits of battery technology, understanding how to care for this component becomes essential for mechanics, technicians, and even knowledgeable owners who want to keep their cars operating safely and efficiently.

The Role of a Battery Clamp in Electric Car Systems

The battery clamp serves as the mechanical interface between the battery terminals and the vehicle’s high‑voltage cabling. In a typical electric car, the battery pack consists of thousands of individual cells grouped into modules. The clamp secures the module’s terminal to the vehicle’s wiring harness, creating a low‑resistance path for power flow. Because electric cars draw substantial current—often exceeding 400 amps—any contact resistance or mechanical looseness can lead to heat build‑up, voltage drops, or, in worst cases, electrical fires. By maintaining a firm, corrosion‑free connection, the battery clamp plays a pivotal role in overall vehicle safety and performance.

Materials and Construction

High‑performance battery clamps are typically fabricated from copper or copper‑alloy housings, which provide excellent conductivity and resistance to oxidation. The clamp body is usually heat‑treated to increase strength, while the contacts are often plated with gold or nickel to prevent corrosion under high humidity or salt‑spray conditions. Many clamps also feature a spring‑loaded mechanism or lock‑nut system that ensures consistent tension on the terminal, even after repeated vibration cycles. This combination of robust materials and precise engineering allows the clamp to endure the harsh operating environment found inside an electric vehicle’s battery enclosure.

- Copper core for low resistance

- Gold or nickel plating to resist corrosion

- Heat‑treated housing for durability

- Spring‑loaded or lock‑nut tension system

Installation Procedures for Technicians

When replacing or inspecting a battery clamp, technicians should follow a systematic approach to avoid damaging the battery module or creating a hazardous condition. First, ensure the vehicle is powered off and the high‑voltage system is isolated; many service manuals recommend a minimum of 30 minutes of standby to allow residual charge to dissipate. Next, verify that the clamp’s alignment pins match the terminal’s mating grooves. A loose or misaligned clamp can cause arcing and heat buildup. Tighten the clamp using the manufacturer’s recommended torque specifications, which are often in the range of 70–90 Nm for large modules. Finally, double‑check the connection with a multimeter to confirm continuity and low resistance.

Safety Considerations and Best Practices

Working with high‑voltage components requires strict adherence to safety protocols. Always wear appropriate personal protective equipment—such as insulated gloves, safety glasses, and flame‑resistant clothing—when handling battery clamps. Additionally, use insulated tools and avoid contact with metallic surfaces that could inadvertently bridge the high‑voltage gap. In environments where static electricity is a concern, grounding yourself before touching the clamp is crucial. Finally, keep the service area well‑ventilated and free of flammable materials, as a poorly installed clamp can generate sparks or heat that may ignite surrounding components.

Troubleshooting Common Clamp Issues

Despite their robustness, battery clamps can develop problems over time. The most common symptoms include:

- Reduced vehicle performance or sudden power loss during acceleration.

- Excessive heat at the clamp’s housing, often detected by a warm feel or visible discoloration.

- Visible corrosion or pitting on the contact surfaces.

To diagnose, first check for visual signs of wear or corrosion. Use a resistance meter to measure contact resistance; a reading above 0.1 milliohm typically indicates a fault. If corrosion is present, clean the contacts with a specialized electrical cleaner, reapply a thin layer of anti‑corrosion spray, and retighten the clamp. Persistent issues may require clamp replacement or, in extreme cases, a full battery module inspection.

Maintenance Tips for Longevity

Proactive maintenance can significantly extend the life of a battery clamp. Inspect clamps at each scheduled service interval—most manufacturers recommend every 12,000 to 15,000 miles. During inspection, look for:

- Looseness or wobble in the clamp body.

- Discoloration or signs of overheating.

- Any gaps or misalignments between the clamp and the terminal.

Apply a light coating of dielectric grease on the contacts after cleaning; this barrier reduces moisture ingress and prolongs the seal. Additionally, avoid exposing the battery enclosure to extreme temperatures; high ambient heat can accelerate material degradation. By incorporating these steps into regular maintenance, technicians can prevent many clamp‑related failures before they manifest as costly service events.

Future Trends: Smart Clamps and Integrated Diagnostics

As electric car technology advances, so does the sophistication of their components. One emerging trend is the integration of smart sensors within battery clamps. These micro‑sensors can monitor temperature, vibration, and contact resistance in real time, transmitting data to the vehicle’s central computer. With predictive analytics, the system can alert owners or technicians before a clamp failure becomes critical, enabling preventative maintenance rather than reactive repairs. Another trend involves the use of advanced composites or shape‑memory alloys to improve mechanical stability while reducing weight, further enhancing vehicle efficiency.

Case Study: Battery Clamp Failure in a High‑Performance EV

“During a routine diagnostic check, a 2019 performance electric sedan exhibited intermittent power loss under full load. The investigation revealed a corroded battery clamp that had degraded due to prolonged exposure to road salt. Replacing the clamp restored full functionality and prevented a potential safety incident.” – Vehicle Service Bulletin, 2024.

This real‑world example underscores how seemingly minor components like the battery clamp can have disproportionate effects on performance and safety. By addressing the issue promptly, the service team not only saved the customer from a potential breakdown but also avoided further damage to the battery module and associated electronics.

Choosing the Right Battery Clamp for Your Vehicle

When selecting a replacement clamp, consider factors such as current rating, material grade, and compatibility with the vehicle’s specific battery architecture. OEM parts are often the safest choice, as they are engineered to fit exact specifications. However, high‑quality aftermarket clamps can offer improved performance or cost savings, provided they meet the same electrical and mechanical standards. Always verify the clamp’s compliance with safety certifications—such as UL or IEC—and confirm that it is approved for use in the vehicle’s electrical system.

Summary of Key Takeaways

The battery clamp, though small, is a linchpin in electric car reliability and safety. Key points include:

- It secures high‑current connections between battery modules and the vehicle’s wiring harness.

- Proper materials and construction mitigate corrosion and heat buildup.

- Installation demands strict torque specifications and safety protocols.

- Regular inspection and maintenance prevent performance degradation.

- Emerging smart clamp technologies promise predictive maintenance and enhanced durability.

By treating the battery clamp with the attention it deserves—through careful selection, meticulous installation, and proactive maintenance—mechanics and owners alike can ensure that electric vehicles deliver on their promise of clean, reliable, and efficient transportation.