Electric vehicles are becoming a staple of modern transportation, and at the heart of every electric car lies the battery cell. The continuous refinement of battery cell technology is reshaping the landscape of car performance, range, and reliability. From the integration of solid‑state electrolytes to the use of silicon‑rich anodes, each innovation builds a bridge toward a future where electric cars can compete with, or even surpass, internal‑combustion engines on every front.

Evolution of the Battery Cell in the Automotive World

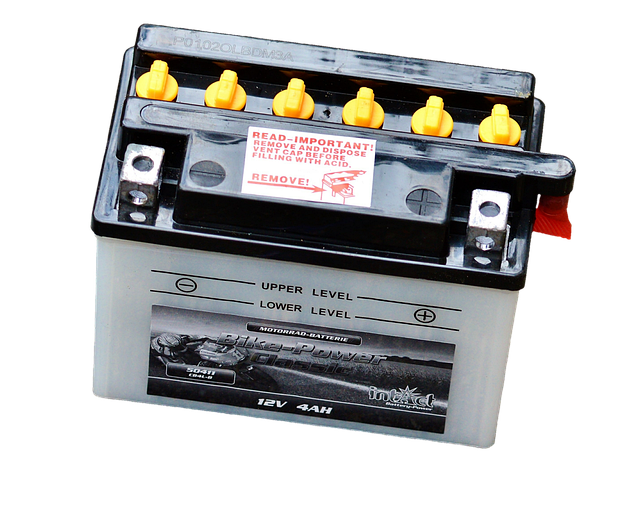

For decades, lithium‑ion battery cells dominated the electric vehicle market. Their high energy density, coupled with relatively low cost, enabled early models like the Nissan Leaf and the Tesla Roadster to break into the mainstream. However, as consumer expectations grew, manufacturers sought improvements in range, charging speed, safety, and lifecycle. The battery cell, once a simple energy storage component, evolved into a complex system that now incorporates advanced materials science, thermal engineering, and sophisticated manufacturing processes.

- Energy Density Increases: Modern battery cells now reach 250–300 Wh/kg, thanks to cathode innovations such as nickel‑cobalt‑manganese (NCM) and lithium‑nickel‑cobalt‑aluminum (NCA) chemistries.

- Thermal Management: Integrated cooling channels and phase‑change materials help keep cells within optimal temperature ranges, reducing degradation.

- Fast Charging: Ultra‑low internal resistance and new electrolyte formulations enable 80 % charging in under 20 minutes for many new models.

Silicon‑Rich Anodes: The Next Leap

Traditional graphite anodes have plateaued in performance. The introduction of silicon‑rich anodes has opened a new frontier for battery cell capacity. Silicon can theoretically store four times as many lithium ions as graphite, promising a dramatic jump in energy density. Although silicon undergoes significant volume expansion during lithiation, researchers have developed composite structures—silicon nanoparticles embedded in carbon matrices—to mitigate mechanical stress.

“The real breakthrough will come when silicon anodes achieve the stability of graphite,” says Dr. Elena Martinez, a materials scientist at the Institute for Advanced Automotive Technology.

Solid‑State Electrolytes: A Game Changer

Liquid electrolytes, while effective, present safety risks such as flammability and leakage. Solid‑state electrolytes replace the liquid component with a solid material—often a ceramic or polymer—offering superior mechanical stability and reduced risk of thermal runaway. The high ionic conductivity of solid‑state electrolytes, combined with their ability to be fabricated at room temperature, makes them an attractive candidate for next‑generation battery cells.

In addition to safety, solid‑state cells can support higher voltage cathodes without degradation, pushing the envelope of attainable energy density. Several manufacturers are now prototyping electric vehicles that incorporate solid‑state battery cells, aiming for ranges exceeding 600 km on a single charge.

Thermal Design and Battery Management Systems

Even with the most advanced battery cell chemistries, thermal control remains critical. An overheating cell can suffer irreversible damage, leading to reduced performance or catastrophic failure. Modern electric car battery management systems (BMS) employ real‑time monitoring of temperature, voltage, and current at the cell level. They can dynamically adjust charging rates, redistribute load across cells, or activate active cooling systems to maintain thermal equilibrium.

- Temperature sensors embedded in each cell module.

- Predictive algorithms that anticipate heat hotspots.

- Active cooling channels integrated into the battery pack structure.

Manufacturing Advances: From Lab to Production Line

Scaling new battery cell chemistries from the laboratory to mass production involves solving complex engineering challenges. Automation of electrode coating, precise control of electrolyte distribution, and stringent quality assurance protocols are essential to produce reliable cells at scale. New roll‑to‑roll manufacturing techniques have reduced production costs by up to 20 %, bringing high‑performance battery cells closer to affordability.

Additionally, advanced diagnostic tools—such as impedance spectroscopy and machine learning‑based defect detection—enable manufacturers to identify sub‑optimal cells before they leave the factory. This proactive approach ensures that only cells meeting stringent performance criteria are integrated into vehicle battery packs.

Recycling and Sustainability of Battery Cells

As the number of electric cars on the road grows, so does the need for responsible battery disposal and material recovery. Modern battery cells are designed with end‑of‑life in mind, featuring modular construction that simplifies disassembly. Chemical recovery processes can reclaim lithium, cobalt, nickel, and aluminum with high efficiency, reducing the environmental footprint of new battery production.

“Circularity is not an afterthought; it’s integral to the battery cell lifecycle,” explains James Liu, head of sustainability at a leading battery manufacturer.

Impact on Car Service and Maintenance

Battery cell improvements extend beyond vehicle performance; they also affect the service experience. Lower degradation rates mean fewer battery replacements, reducing downtime for owners. Furthermore, improved thermal stability decreases the risk of overheating, lowering the incidence of battery‑related service calls. Car service centers are now incorporating diagnostic tools that can read battery cell health metrics directly, allowing for predictive maintenance rather than reactive repairs.

Automotive service technicians are receiving updated training modules focused on battery cell safety, including proper handling of high‑voltage systems, emergency procedures for battery faults, and best practices for battery pack inspection.

Parts Integration: From Modules to Packs

Battery cells are assembled into modules, which are then integrated into a battery pack. Innovations in cell design have led to new module architectures that are more compact and efficient. For instance, 3D‑printed cell housings can reduce weight while providing improved structural support. These design changes streamline the supply chain for car parts, as manufacturers can produce standardized modules that fit a variety of vehicle platforms.

- Standardized cell formats (e.g., 18650, 21700).

- Modular stack designs with built‑in BMS integration.

- Thermal interface materials that double as structural reinforcements.

Current Trends in Electric Car News

The automotive press is buzzing with stories about breakthrough battery cell developments. Recent headlines include:

- Announcement of a new silicon‑rich anode that achieves 300 Wh/kg in commercial production.

- First mass‑produced solid‑state battery car with an 800 km range.

- Strategic partnerships between battery cell manufacturers and automakers to secure supply chains.

- New regulations mandating higher recycling rates for automotive batteries.

These developments underscore the dynamic nature of the electric vehicle ecosystem, where battery cell technology remains the linchpin for progress.

Future Outlook: Beyond the Current Horizon

Looking ahead, researchers are exploring beyond lithium‑ion chemistries. Concepts such as lithium‑sulfur, sodium‑ion, and even aluminum‑ion batteries could further elevate energy density or reduce cost. However, these technologies are still in the experimental stage and face significant hurdles, including safety, cycle life, and material sourcing.

In the near term, battery cell innovations will continue to focus on incremental gains—improving lithium‑ion cells through better cathodes, advanced separators, and smarter BMS—while laying the groundwork for the revolutionary breakthroughs that will define the next generation of electric vehicles.