Mastering Battery Qualification: A Comprehensive Guide for Success

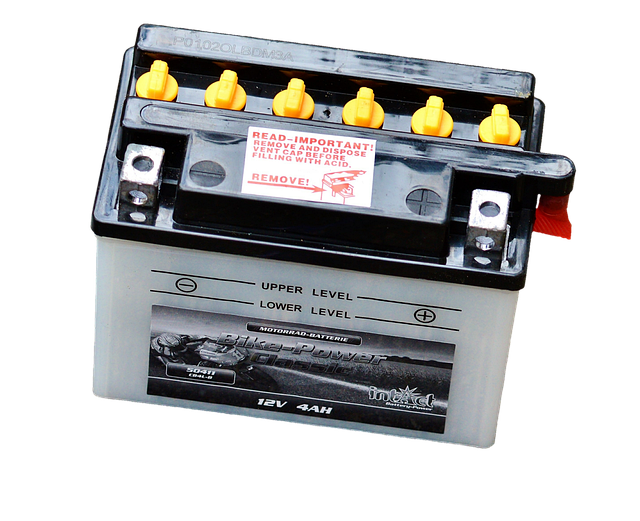

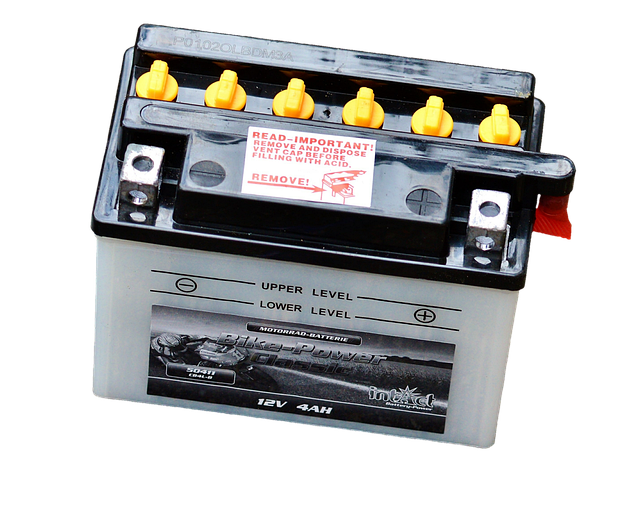

In today’s rapidly evolving world of technology, batteries are the heart that keeps our devices, vehicles, and systems alive and functioning. Whether you’re developing electric vehicles, portable electronics, or large-scale energy storage, battery qualification is a critical step that ensures the reliability, safety, and performance of your battery systems.

Why Battery Qualification Matters

Imagine the frustration of a battery failing prematurely or delivering inconsistent power—this not only affects product reputation but can also compromise safety. Battery qualification is the process that validates a battery’s capabilities against expected real-world conditions, ensuring it meets stringent standards before deployment.

For anyone involved in the battery industry—from engineers to quality assurance teams—grasping the nuances of battery qualification provides confidence that your product will stand the test of time and usage.

Key Components of Battery Qualification

- Performance Testing: Evaluating capacity, energy density, and discharge characteristics to confirm the battery delivers expected power.

- Safety Assessment: Identifying risks such as overheating, short circuits, or leakage through rigorous stress tests and abuse simulations.

- Environmental Stress Testing: Testing battery resilience in extreme temperatures, humidity, and vibration to mimic operational environments.

- Cycle Life Testing: Measuring how the battery’s performance evolves over repeated charge and discharge cycles.

- Compliance and Certification: Ensuring the battery meets regulatory standards such as UL, IEC, or UN38.3 for transportation safety.

Steps to Master Battery Qualification

Mastering battery qualification requires a structured approach:

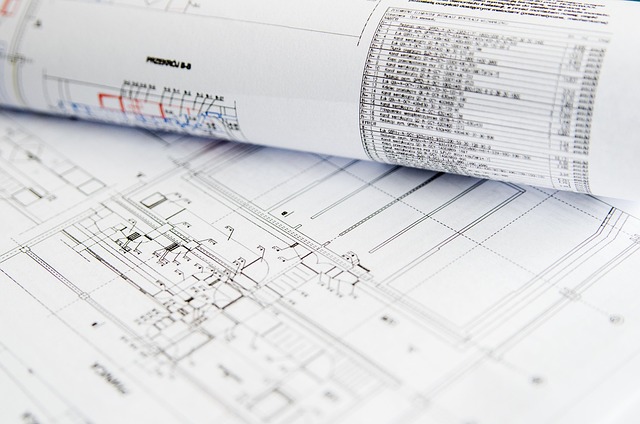

- Define Your Criteria: Establish clear performance, safety, and lifespan goals based on your application.

- Develop a Test Plan: Create comprehensive testing procedures that reflect real-world scenarios your battery will face.

- Select Proper Equipment: Utilize accurate and reliable testing instruments tailored for battery diagnostics.

- Analyze Data Thoroughly: Interpret test results to uncover trends, anomalies, or potential failure modes.

- Iterate and Improve: Use insights gained from testing to enhance battery design or manufacturing processes.

- Document Everything: Maintain detailed records for traceability and certification purposes.

Common Challenges and How to Overcome Them

Battery qualification isn’t without its hurdles. Some of the frequent challenges include:

- Long Testing Times: Cycle life testing can stretch over months; accelerate this by simulating high-stress conditions strategically.

- Complex Data Interpretation: Engage experts or employ software tools to accurately interpret complex datasets.

- Ensuring Test Repeatability: Standardize procedures and calibrate equipment regularly to maintain consistency.

- Cost Constraints: Prioritize tests based on risk and application criticality to optimize budget allocation.

Empowering Your Battery Projects with Confidence

Whether you’re an engineer pushing the boundaries of battery technology or a project manager overseeing product launch, mastering battery qualification empowers you to deliver products that perform reliably, safely, and efficiently. By embracing rigorous testing and validation, you gain the peace of mind that your batteries will endure real-world challenges, powering the innovations of tomorrow.