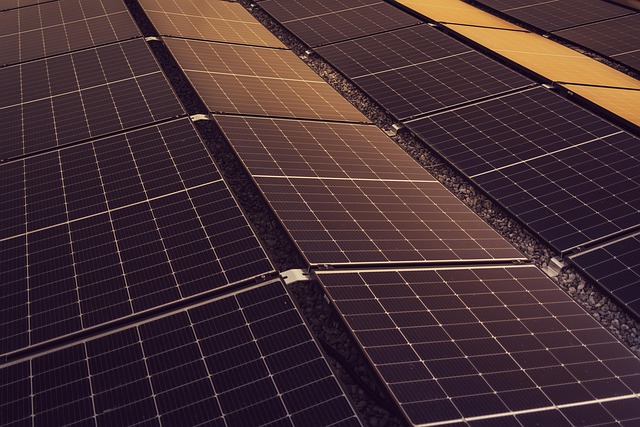

The pulsating core of any modern electric vehicle isn’t the rumble of a traditional engine; it’s the silent, powerful energy stored within its battery pack. And increasingly, the future trajectory of the entire electric vehicle movement is being shaped not just in R&D labs, but directly on the assembly lines and clean rooms of specialized manufacturing facilities – the battery factory.

These high-tech plants are Ground Zero for innovation that directly impacts the *electric car* experience. breakthroughs in cell chemistry, packaging density, and manufacturing scale are reducing costs, increasing range, and speeding up charging times. This isn’t just about making a single component; it’s about revolutionizing one of the most complex and critical *car parts*.

The advancements originating from the *factory battery* directly dictate the performance and efficiency of the electric powertrain, effectively redefining the concept of a car engine” for the 21st century. As energy density increases and weight decreases, designers have more freedom, leading to lighter, more aerodynamic, and ultimately, more capable vehicles. The precision required in manufacturing these complex units on a massive scale is transforming global automotive supply chains.

It’s no surprise that *car news* headlines frequently feature announcements about new ‘gigafactories’ or reports on breakthroughs in manufacturing solid-state or silicon-anode batteries. These aren’t niche technical stories; they are reports on the very foundation being laid for the next generation of transportation.

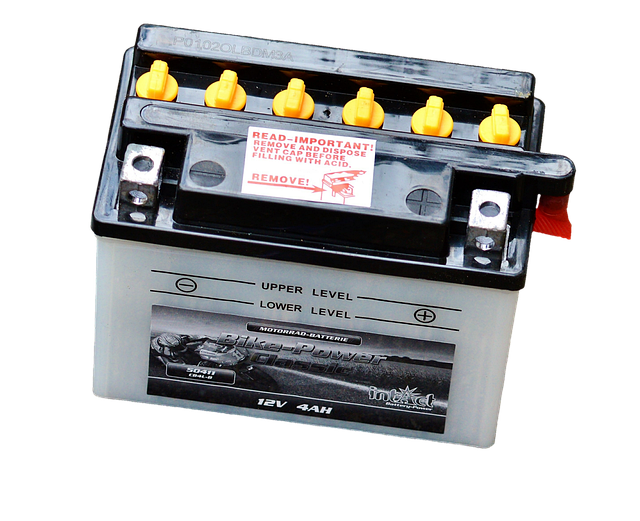

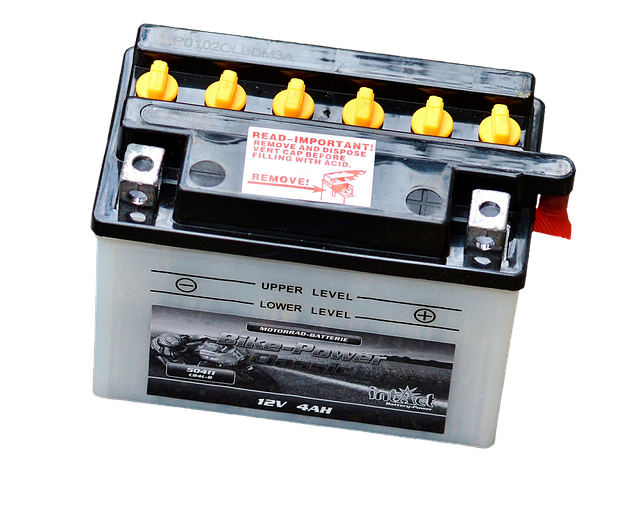

Furthermore, the evolution of the *factory battery* is set to profoundly change the landscape of *car service*. As batteries become more sophisticated and integral to the vehicle’s structure and operation, service centers will need new diagnostic tools, specialized training for technicians, and protocols for battery health management, repair, and eventual recycling. The long-term durability and maintenance considerations are being baked into the battery design and manufacturing process itself.

Ultimately, the quiet, large-scale advancements happening inside the *factory battery* facilities are the driving force behind making the *electric car* more accessible, performant, and sustainable. These innovations are not just improving a component; they are powering a global shift in how we build, maintain, and experience personal transportation.