In the rapidly evolving world of electric vehicles (EVs), one term is becoming increasingly pivotal: battery logistics. As the electric car industry gains momentum, the logistics surrounding battery management are emerging as a cornerstone for sustainability, efficiency, and innovation.

Electric cars are no longer the vehicles of the future; they are the cars of today. With major manufacturers committing to electrification, the need for effective battery logistics has never been more critical. Imagine the intricate dance of car parts, engines, and supply chains working seamlessly to ensure that each electric vehicle provides not just performance, but also reliability and longevity. This is where battery logistics plays a defining role.

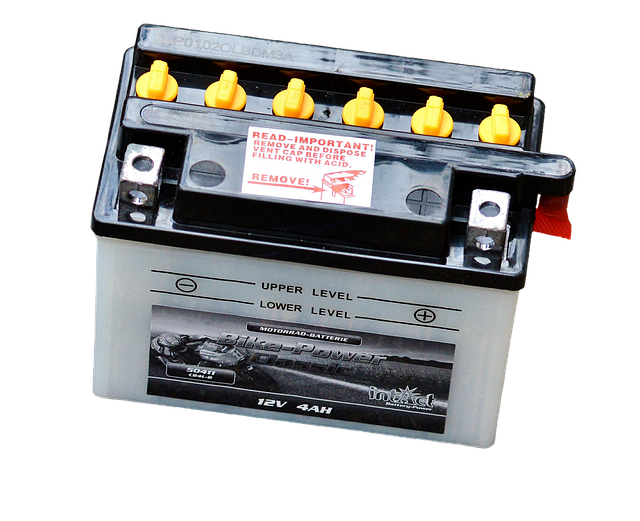

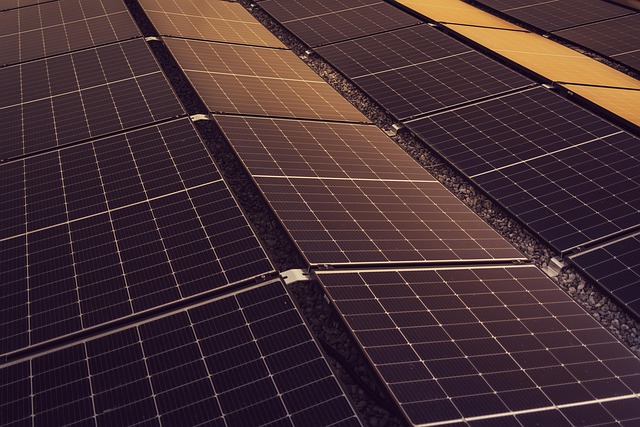

The battery is to an electric car what the engine is to a traditional gasoline car—a crucial element that determines performance. Without efficient management of batteries, from production to recycling, the potential of EVs remains untapped. Companies are investing in creating streamlined battery supply chains, introducing innovative methods for transportation and storage that minimize costs and maximize energy efficiency. Imagine a world where batteries can be charged using renewable energy sources, stored effectively, and then delivered to the car service center as needed. It’s a game-changer.

News surrounding electric cars continues to unfold rapidly. From breakthroughs in battery capacities to advancements in charging technologies, every development impacts how we perceive battery logistics. Consider the logistical challenges faced when sourcing raw materials necessary for battery production. The industry must transition to sustainable practices and build robust recycling programs to deal with the growing volume of used batteries. Each time a battery cycle is completed, it represents a chance to drive forward sustainability in automotive manufacturing.

As electric vehicles become increasingly mainstream, consumers will need to understand how battery logistics affects not just vehicle performance but also the environment. Regular car services will evolve, as technicians will become more specialized in handling the unique needs of EV batteries and their components. New workshops will pop up, focusing solely on battery management and maintenance, ensuring that these vehicles run efficiently throughout their life cycles.

The integration of smart technologies into battery logistics is another exciting frontier. Real-time tracking, predictive analytics, and automated systems will reshape how batteries are managed in transit—ensuring that every electric car is equipped with a fully charged and reliable battery when it arrives at its destination.

Keep an eye on the automotive news landscape. As technology progresses and battery technology continues to improve, the implications for battery logistics will be profound. Innovations in logistics could reduce these costs and provide a stable supply of energy needed to power the electric vehicles of tomorrow.

In this dynamic landscape, battery logistics stands at the forefront, integrating seamlessly with the broader narrative of electric vehicles, car parts, and efficient service life. The road ahead is laden with promise, presenting both challenges and opportunities that will ultimately define the future of the electric car industry.